Monetizing IoT: Extracting Value from the Connectivity Opportunity

The power of IoT drives endless possibilities. Its large mesh of complex, scattered, and fragmented networks continue to blur the boundaries between products and services. Today, it may seem all too easy to get caught up in the limitless possibilities of “digital transformation” and “Industry 4.0,”. However, the process of transforming chunks of unstructured data into intelligent insights is much more than merely installing sensors and using an analytics program.

IoT implementations are typically marred by two primary challenges. Firstly, cybersecurity – with more systems going online every day there is a consistent rise in systems’ vulnerability to malware attacks and security breaches. This creates an air of scepticism in terms of security amongst users. However, advancements in the field cybersecurity have helped reinforce security features and keep a check on such invasive elements.

The second and even more challenging roadblock is the ability to efficiently monetize the investment made in IoT. Beyond the function of data collectors, the real challenge lies in translating this data intelligent insights to deliver value to all the stakeholders in the product chain. In other words, the data must convert into value for the product developer (capital manufacturer), product user (product manufacturer), and end users of the produce. Investment in IoT can be justified when it is able to demonstrate value across the entire value stream. This is where most players fail. The value demonstrated should also be able to be passed on to all those across the value chain, otherwise the essence of IoT implementation would be incomplete.

Ideally, this can be achieved by combining devices, data, and analytics to produce new, business-relevant insights. For this, applications need to be integrated into multiple endpoints. Here is where the challenge truly lies. These endpoints can be an IoT and network domain, but they can also be an IT system (CRM, ERP, or billing, to name a few).

For an industrial equipment manufacturer, in terms of IoT implementation there are 4 ways in which they can deliver value

1. Profitability Improvement – The data derived can help the production in several ways. Some common examples are increased productivity, direct impact on profitability, cost-effective solutions – enabling the production of much more for much less.

2. Product Performance – Insightful intelligence about different sub-assemblies, parts, and components and product usage which will explain a lot of unexplained failures, downtimes, customer complaints. The intelligence can impact customer to develop better products and leverage the investment on existing R&D. So instead of starting from the scratch, a revised version can be released using existing product performance.

3. Revenue – There can be several ways in which the value derived from IoT implementation can be converted into revenue.

The IoT path offers multiple channels of monetization. For instance, what was previously a $200,000 capital expenditure can now be easily converted into operational expenditure by means of pay-per-use or adopting time-sharing models. This can trickle down benefits in a number of ways. A large company can now effectively monetize from its equipment by sharing it with smaller companies that do not have the capability of production.

It can also allow a large company streamline efficiencies in all its plants. For instance, it can effectively replace 5 plants that are functioning at 60% efficiency with 3 plants that achieve more than 98% efficiency.

The data of can also empower operators in better manufacturing decision making. The intelligence within these data can also be sold as a service.

4. Customer Satisfaction – And finally IoT implementation can also drive and deliver promising customer satisfaction. The intelligence drawn from these services can be used to prevent, predict failures, suggest better usage behaviours, and thereby reduce the chances of downtime or failures for the customer. These factors can effectively deepen engagement between partnerships.

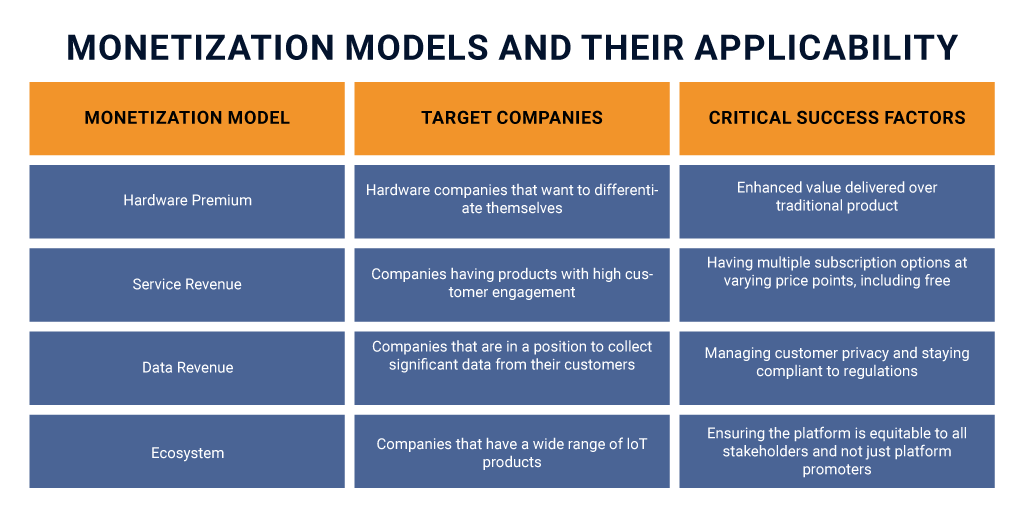

No One-Size-Fit-All Model for IoT Monetizing IoT implementation

There are multiple channels that can be effectively tapped and monetized. This means there is no one-size-fit-all model to monetize IoT implementation. The following table gives a brief overview of how different models are suited across different sections. The critical success factors will be key to helping companies maximize the returns from each stream.

Merraky is a global engineering services company providing best-in-class engineering design in embedded electronics, mechanical engineering, and manufacturing engineering. Headquartered in Bangalore, India, the company also has global operations in UK, USA, and Italy.